The Japan Industrial Standards (JIS) is a system of national standards established to ensure the quality, safety, and efficiency of products and services in Japan.

First Published: 2021-06-16

Updated: 2024-07-29

Table of Contents

- What is JIS? The Importance of Industrial Standards

- History and Development of JIS

- JIS Classification and Numbering System

- Benefits of JIS

Are you having any issues with job-hunting in Japan?

Are you having any issues with job-hunting in Japan?

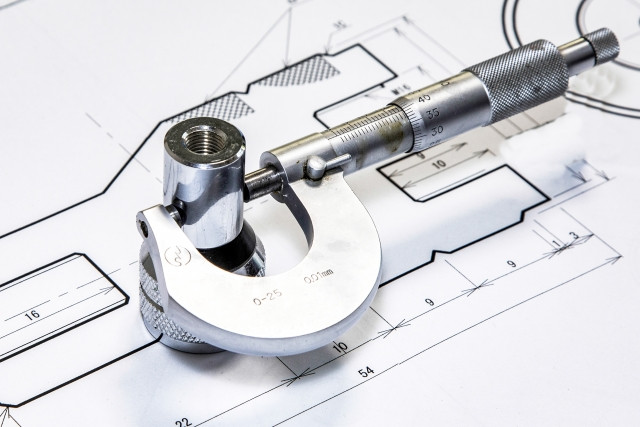

What is JIS? The Importance of Industrial Standards

Image from Japanese Industrial Standards Committee

The Japan Industrial Standards (JIS), called 日本産業規格 (Nihon Sangyou Kikaku) in Japanese, is a system of national standards established to ensure the quality, safety, and efficiency of products and services in Japan. Managed by the Japanese Industrial Standards Committee (JISC), under the Ministry of Economy, Trade, and Industry (METI), JIS provides guidelines that cover a wide array of industries, including manufacturing, engineering, and consumer goods. These standards are pivotal in maintaining product consistency, fostering innovation, and enhancing Japan's industrial competitiveness on a global scale.

Writer's Pick

History and Development of JIS

The origins of JIS can be traced back to the early 20th century, during Japan's rapid industrialization. There was an increasing need for standardized specifications to support the growth of the manufacturing sector and ensure the reliability of products.

Major Milestones

- 1921: Adoption of Japanese Engineering Standards (JES) promulgated by the establishment of the Japanese Engineering Standards Committee (JESC)

- 1949: The formal establishment of JIS under the Industrial Standardization Law along with the Japanese Industrial Standards Committee (JISC) to oversee and coordinate the standardization efforts..

Recent Updates

In recent years, JIS has undergone several revisions to keep pace with technological advancements and globalization. Notable updates include the incorporation of standards for digital technologies, green manufacturing practices, and sustainable development.

JIS Classification and Numbering System

The JIS framework is managed by the Japanese Industrial Standards Committee (JISC), which operates under the Ministry of Economy, Trade, and Industry (METI). JISC collaborates with various industry stakeholders, academic institutions, and governmental bodies to formulate and update standards.

JIS Classification

JIS standards are categorized into several groups:

A: Civil Engineering and Architecture

B: Mechanical Engineering

C: Electronics and Electronic Engineering

D: Automotive Engineering

E: Railway Engineering

F: Shipbuilding

G: Iron and Steel

H: Nonferrous Metals

K: Chemical

L: Textiles

M: Mining

P: Pulp and Paper

Q: Management System

R: Ceramics

S: Domestic Wares

T: Medical Equipment and Safety

W: Aviation

X: Information Processing

Y: Service

Z: Others

JIS Numbering System

Each standard in JIS is assigned a unique code consisting of an alphabetical prefix (indicating the category) followed by a numerical code. For example, "JIS G 3112"refers to a steel bar for reinforced concrete building construction

When a revision is applied to the classification, then the year will be added after the currently existing number. In this case, if you see “JIS G3112:2010”, then you know it was revised in 2010.

The latest JIS numbers are listed on the JISC official website.

※ JISC, “産業標準化とJIS”

As the above list shows, the application of JIS in industry sectors provides a certain set of methods which can be updated over time according to the particular department concerned. This also assures strict adherence to quality standards for consumers at large, as well as the reliability of products in the market.

Monthly establishment and revision of Japanese Industrial Standards (JIS) are performed and updated as revisions are made. The English versions of the updates and news on JIS are published by Japan Standards Association Group (JSA) in order to ensure that everything related to international trade and business is also kept up to date on such changes.

Benefits of JIS

There are many benefits of JIS, mainly:

- Quality Assurance - JIS standards provide a framework for maintaining high-quality production processes, ensuring that products meet specific performance and safety criteria.

- Compatibility and Interoperability - Standardization ensures that products and components are compatible with each other, facilitating seamless integration and interoperability in various applications.

- Economic Advantages - By adhering to JIS standards, companies can reduce production costs, minimize errors, and improve marketability, leading to economic benefits and competitive advantages.

To Close

Japan Industrial Standards (JIS) are integral to maintaining product quality, safety, and international competitiveness for Japanese industries. Through continuous updates and adherence to global trends, JIS will continue to play a crucial role in shaping the industrial landscape of Japan and contributing to global standardization efforts.