In this article, we introduce Japan’s manufacturing industry in recent years. Find out what occupations and types of manufacturing jobs in Japan there are and why you should work in Japan’s manufacturing industry.

Table of Contents

- A Look at Japan’s Manufacturing Industry

- Main Sectors in Japan’s Manufacturing Industry

- Manufacturing Jobs in Japan and What They Entail

- Advantages and Disadvantages of Working in Japan’s Manufacturing Industry

- Characteristics of People Suited for the Manufacturing Industry

- Find a Job in Japan with WeXpats

Are you having any issues with job-hunting in Japan?

Are you having any issues with job-hunting in Japan?

A Look at Japan’s Manufacturing Industry

.jpg)

The manufacturing industry, called “製造業 (Seizougyou)” in Japanese, involves assembling and processing raw materials and resources to produce and sell products. The Japanese Ministry of Economy, Trade and Industry (METI) defines manufacturing businesses as “those primarily engaged in the manufacturing and processing of new products” and “those that mainly wholesale manufactured and processed new products”. In other words, the manufacturing industry encompasses the entire process from production to sales.

Japan has 3 main categories of industries (産業, Sangyou): Primary, Secondary and Tertiary industries. The primary industry involves natural resources, such as producing and harvesting crops, e.g. agriculture, fisheries, and forestry. The secondary industry involves processing natural resources, e.g. construction and manufacturing. Lastly, the Tertiary Industries are industries that do not fall under either primary or secondary industries, e.g. commerce, finance and services.

The manufacturing industry is a key pillar that supports Japan’s economy. In 2022, it accounted for about 20% of Japan’s GDP, making it the second-largest industry after services. Additionally, a labor force survey by Japan’s Ministry of Internal Affairs and Communications in 2023 showed that roughly 10.55 million people were employed in manufacturing, making it the country’s largest sector in terms of employment, out of a total workforce of about 67.47 million.

※ METI, “工業統計調査 用語について”, “令和5年度 ものづくり基盤技術の振興施策” ※ Statistics Bureau of Japan, “労働力調査(基本集計) 2023年(令和5年)平均結果”

Writer's Pick

Main Sectors in Japan’s Manufacturing Industry

.jpg)

Japan’s manufacturing industry encompasses various sectors. It is not limited to producing automobiles, machinery, parts and home appliances. In this part, we introduce some of the main sectors in the manufacturing industry.

Machinery-related (Automotive Industry, etc.)

Machinery-related industries handle the design, production, and assembly of mechanical products. They produce a broad range of machinery, from familiar items like cars and home appliances to industrial equipment and research devices used in factories. A key characteristic of this sector is the wide variety of products it handles.

Recently, industrial robots and AI have been introduced, making it one of the most efficient sectors in manufacturing.

Metal and Steel

This sector mainly produces metal and steel products used in machinery and building components. Metal and steel are essential in everything from large construction projects like bridges and buildings to smaller items like screws, computer parts, and car bodies.

Recently, this industry has also emphasized recycling used metals and steel.

Chemical Products

Using raw materials like oil and natural gas, chemical manufacturers create products and materials through chemical reactions. This sector produces various items, including synthetic fibers for clothing, adhesives, films, plastic bottles, and food ingredients. Known for its advanced technological requirements, this field supplies essential materials and products for daily life.

A characteristic of the chemical-related sector is that many companies are involved in the entire process from procurement of raw materials to commercialization of products.

Food-related

This sector manufactures a variety of food products, such as snacks, beverages, canned goods, and processed foods. It also involves a wide range of tasks, from planning new products to sales.

In recent years, many food-related manufacturers have increasingly adopted production lines and robots rather than relying on manual labor.

Construction and Housing

Construction and housing-related manufacturing doesn’t just build houses and buildings; it also constructs large structures like roads and bridges. Additionally, it manufactures interior parts, windows, and frames for homes.

In recent years, as demand for remodeling and renovating old traditional houses has increased, more and more companies are focusing on manufacturing materials used for remodeling.

Pharmaceuticals

The pharmaceutical manufacturing industry produces medicines that are both prescription-based and over-the-counter. It also engages in unique tasks such as research, development of new drugs, and clinical trials. Given the rising awareness of health, the pharmaceutical sector plays an essential role in supporting people’s health and lives.

Timber and Wooden Products

Wood product manufacturers handle timber processing and assembly to produce various items. This includes manufacturing building materials, assembling furniture like beds, chairs, and tables, and cutting or pressing lumber. Some companies are involved not only in production but also in design and planning.

Japan, often called a "manufacturing powerhouse," exports many domestically made products internationally. As a result, factories crucial to production are generally located along coastlines, where transportation and exporting are more convenient.

Manufacturing Jobs in Japan and What They Entail

.jpg)

The manufacturing industry includes various roles, such as design, planning, development and sales. Here are some key roles and their main responsibilities in manufacturing.

.png)

Product Planning

Product planners develop products based on market trends and customer needs, gathering information on what consumers want. They aim to leverage the company’s strengths to create unique products that stand out from competitors.

This role involves market research and competitive analysis, so marketing skills are essential. Planners also coordinate with other departments on materials procurement, pricing, and sales strategies, making communication skills and creativity crucial.

Research and Development (R&D)

R&D focuses on researching new technologies to develop new products. Based on research results, they assess whether the company can produce products that meet customer demands and market trends from a technical standpoint. R&D also works on improving existing products, making it an indispensable role in creating better products for manufacturing and sales.

Design

Designers turn product ideas into blueprints, defining structures and specifications to ensure feasible manufacturing. Since there are budget and technical limitations, designers create plans that enable production within the given constraints. As consumer demands evolve, designers need to stay up-to-date on the latest technologies and expand their knowledge base.

Materials Procurement

Materials procurement involves sourcing and securing the raw materials needed for production. This role includes finding suitable materials, selecting suppliers and wholesalers, and ensuring budget compliance and adequate quantities. If budgets are exceeded, they negotiate prices or explore alternative suppliers. This position plays a vital role, as materials impact product pricing, quality, and production.

Production Management

Production management oversees the entire manufacturing process based on sales plans. Manufacturing has strict deadlines, so production managers coordinate equipment, personnel, and process management to meet delivery dates. When production doesn’t proceed as planned, production managers must make prompt decisions. Involvement throughout the entire process from start to finish makes this a fulfilling role.

Production and Manufacturing Technology

Production involves creating products in factories following designs and instructions. If products don’t meet standards, production identifies issues and makes improvements.

Manufacturing technology, meanwhile, focuses on producing quality products efficiently, suggesting improvements on the production floor. For example, this might involve optimizing workflows or addressing equipment issues. Manufacturing engineers focus on technical improvements across each step of the production line.

Quality Control and Inspection

Quality control and inspection ensure products meet standards and detect defective items. Maintaining quality prevents accidents and safeguards the manufacturer’s reputation. Quality control is critical in industries where product defects could impact lives, such as machinery, automotive, or pharmaceuticals. Quality inspections during production include:

- Incoming Inspection (checking the quality of raw materials or parts)

- In-process Inspection (inspecting products mid-production to prevent defects from advancing)

- Final Inspection (checking the finished product for quality and safety before shipment)

Quality control and inspection helps quickly identify and address issues, building customer trust.

Sales and Marketing

Sales and marketing involve selling manufactured products or custom-made items based on client requirements, playing a key role in generating profit.

Manufacturing companies primarily focus on B2B (business-to-business) sales. For example, raw material manufacturers usually sell to companies that produce or assemble parts. Similarly, assembly companies often sell to wholesalers rather than directly to individuals.

Sales require coordination with other departments, like planning, design, and production management, to meet customer needs, making strong internal and external relationships essential.

Advantages and Disadvantages of Working in Japan’s Manufacturing Industry

.jpg)

The manufacturing industry is relatively accessible for those without work experience, and certain roles or product areas offer the potential for high income. However, some people may have a negative perception of working in manufacturing. Here is an overview of the pros and cons of working in the manufacturing industry.

Advantages of Working in the Manufacturing Industry

.jpg)

The manufacturing industry produces essential products and parts for daily life, offering stable employment and income. Here are some benefits of working in manufacturing:

Well-Structured Work Environment

A key advantage of manufacturing is its stable work and break schedules. With many facilities operating 24/7, work and break times are clearly defined. Additionally, more companies are providing employee housing and improving employee benefits, creating a supportive work environment.

Accessible to Those Without Work Experience

Manufacturing is known for being accessible to individuals without prior work experience. Many companies focus on an applicant's attitude and work ethic rather than experience or specific skills. Most companies also have strong training programs, with detailed manuals and workshops to support employee development from the ground up.

Opportunities for Career Advancement Regardless of Education

Many manufacturing companies do not require specific educational qualifications. Although certain positions may require specialized knowledge or skills, many companies offer support for earning certifications. Those who are motivated can build their technical expertise and advance their careers.

High Earnings Potential

Manufacturing often offers competitive salaries and benefits. Income varies by role, location, and skill level, but certain departments like R&D and production management tend to offer high earnings. Generous additional pay, such as qualification, night, and special duty allowances, also make it easier to aim for higher income in this industry.

Minimal Overtime

Some manufacturing roles have minimal overtime, supporting a good work-life balance. While busy seasons and unfinished tasks can lead to overtime, many employees are typically able to leave on time. This can be an ideal work environment for those who want to maintain private time and balance between work and personal life.

Suitable for Those Who Prefer Minimal Customer Interaction

Certain roles, such as assembly line work, involve minimal customer interaction, unlike sales or customer service roles. Some positions allow employees to work independently in their assigned areas, although basic manners like greetings and responses are still essential.

Disadvantages of Working in the Manufacturing Industry

.jpg)

The work style in manufacturing varies widely depending on the type of role and products handled. However, some people associate the industry with physically demanding work or repetitive tasks. Here are some of the challenges of working in manufacturing:

Image of Being a Physically Demanding and Difficult Job

Many people think this about the manufacturing industry. Compared to desk jobs or other industries, manufacturing jobs often involve more hazardous tasks, increasing the risk of injury or accidents. However, most manufacturing companies today have made efforts to improve and review working conditions, with considerable emphasis on safety, work hours, and hygiene standards.

Physical Stamina is Essential for Standing Work

Physical stamina is essential when working in manufacturing. Many roles, particularly on production lines, involve long periods of standing or carrying heavy items. Those without strong physical endurance may find it difficult to adjust to the work at the beginning.

Repetitive Tasks Requiring Focus

Certain roles involve repetitive tasks, requiring the same motions repeatedly. This can make it easy to lose focus, increasing the risk for errors. Success in such roles requires the ability to stay focused and find enjoyment or satisfaction in the routine.

Characteristics of People Suited for the Manufacturing Industry

.jpg)

Manufacturing offers a variety of roles, but generally requires understanding and following blueprints and manuals precisely. Here are some qualities of people who are well-suited for manufacturing work. If you’re interested in this field, consider whether these apply to you.

Physically Fit

Confidence in physical ability is essential for manufacturing, as it often involves standing work and handling heavy materials. Also, many manufacturing jobs operate a shift system, including night shifts, meaning that adjusting to a variable schedule can require stamina and resilience.

Focused and Patient

People who can work steadily with a high level of focus are well-suited for manufacturing. Repeating the same tasks on a production line is common, so those who can maintain attention to detail and perform repetitive actions accurately are ideal. The work often involves inspections and reporting, making cautious and attentive individuals a great fit.

Skilled at Streamlining Work

Those who excel at optimizing processes are well-matched to manufacturing. Roles often require completing tasks within a limited time frame, so productivity and efficiency are highly valued. People who can set personal goals and actively seek to improve workflow often find manufacturing work particularly rewarding.

Find a Job in Japan with WeXpats

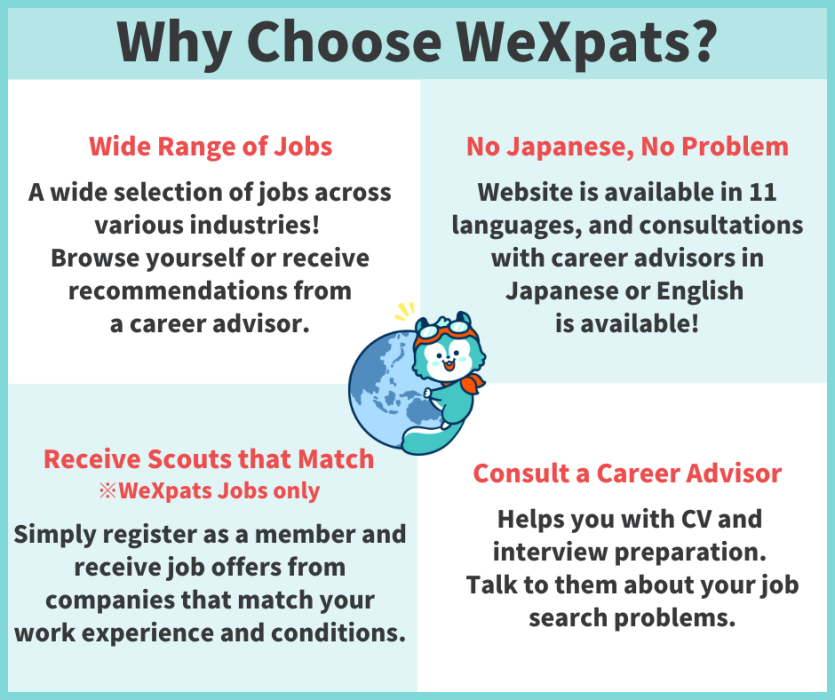

WeXpats operates a service for foreign nationals who want to work in Japan. There are jobs in a variety of industries. There are 2 services available on WeXpats - WeXpats Agent for full time jobs and WeXpats Jobs for part time jobs.

Looking for a Full Time Position? Leave it to WeXpats Agent!

WeXpats Agent is a career support service that specialises in employment for foreign nationals living in Japan.

Recruitment agencies in Japan are a service where dedicated career advisors will assist you with your job hunt for free. In addition to introducing open positions, we also provide support to help you create your Japanese resume and practice for interviews. Worried about job hunting in Japanese? We are here for you.

Features of WeXpats Agent

-

We have many job openings that are a good fit for foreign nationals to work in, such as translation, interpretation, inbound, etc. jobs that make use of your language skills, as well as engineering etc. jobs that do not require Japanese skills.

-

Our career advisors support and help you prepare your resume and practice job interviews with you. Clearly communicate your strengths to the hiring company.

-

We will handle communication with companies on your behalf, such as arranging interview dates and negotiating conditions. And thereby reducing your stress and time spent.

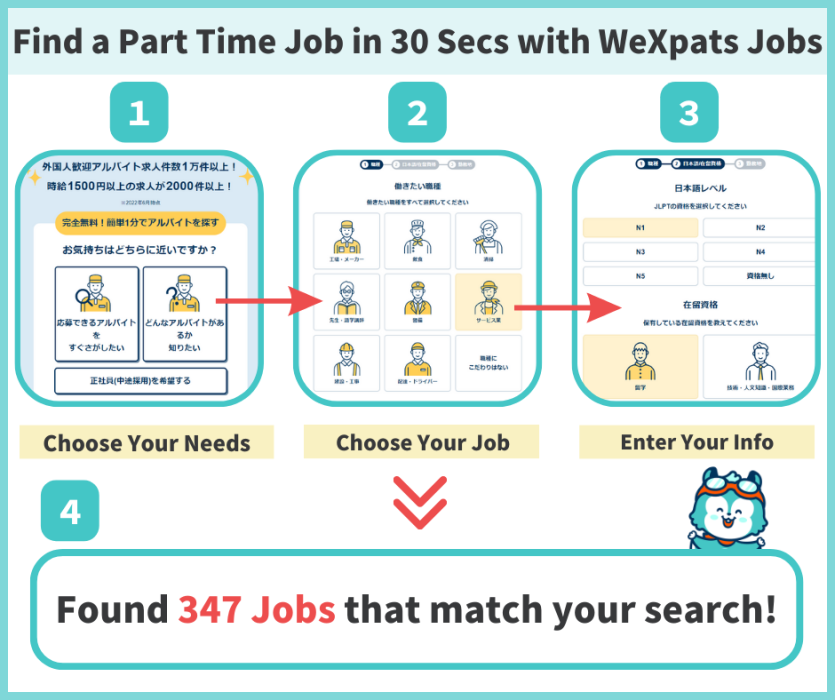

Finding a Part Time Job? Browse on WeXpats Jobs!

WeXpats Jobs is a part time job site for foreign nationals living in Japan. You can search for jobs in 11 languages (English, Vietnamese, Korean, Indonesian, Traditional Chinese, Simplified Chinese, Burmese, Thai, Spanish, Portuguese), including Japanese. Find jobs that suit you by specifying your Japanese language level, occupation, location, and etc.

※ You can register from outside Japan, but only those living in Japan can apply for jobs.